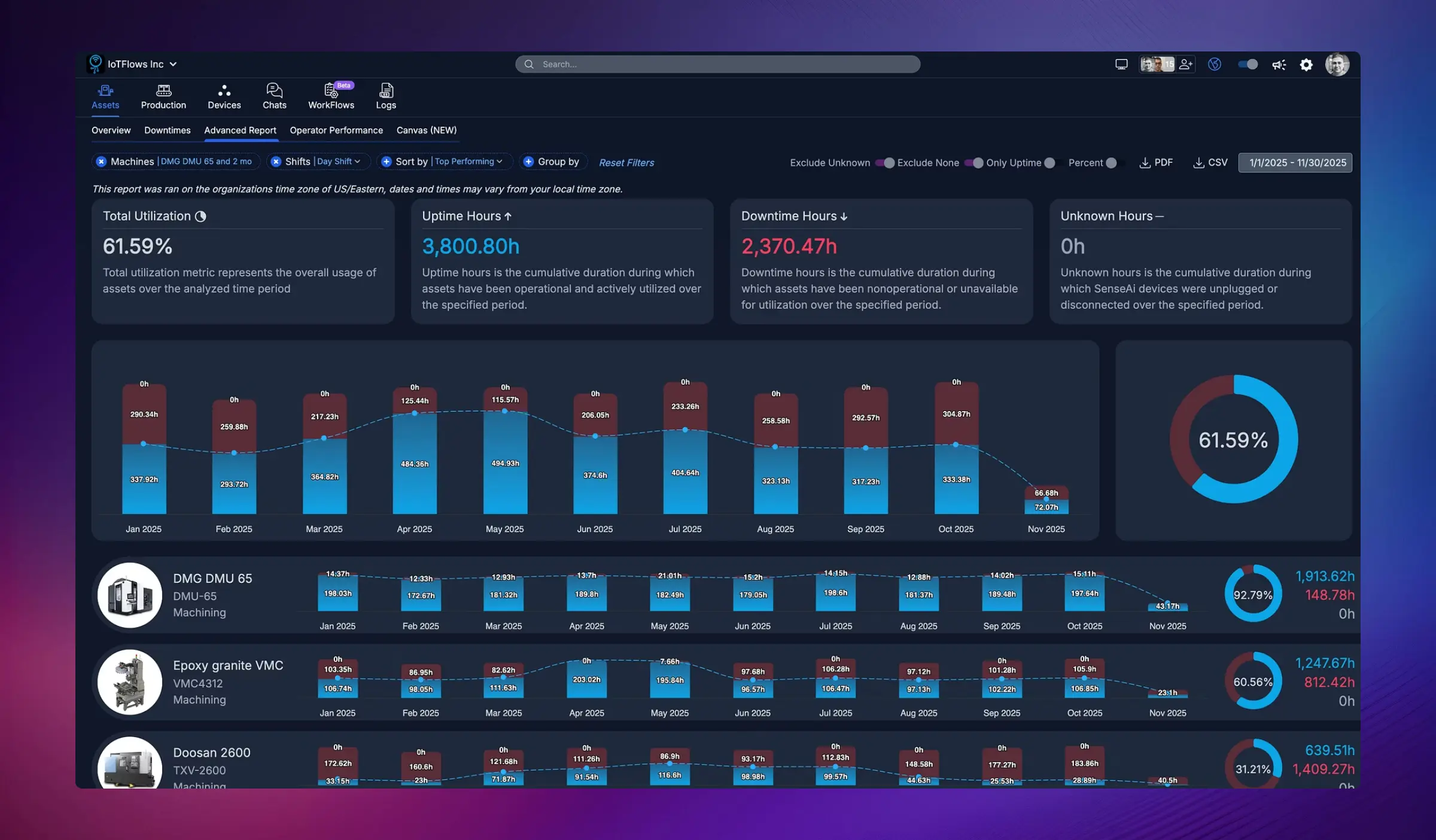

Advanced Report

Generate custom utilization and performance reports with advanced filtering by machine, department, shift, date range, and time interval.

Overview

The Advanced Report is your most powerful analytics tool for deep-dive analysis of machine utilization, performance, and production data. Unlike real-time dashboards, Advanced Report lets you create highly customized reports with precise filtering, date range selection, and time interval grouping to answer specific operational questions.

Perfect for:

- Monthly or quarterly performance reviews

- Comparing departments or shifts

- Tracking improvement initiatives over time

- Generating executive reports and KPI summaries

- Analyzing specific time periods or events

- Exporting data for external analysis

Key Features

Comprehensive Filtering

Filter your analysis by multiple criteria simultaneously:

By Machine/Asset

- Select specific machines

- Choose multiple assets for comparison

- Include all machines in a department

- Filter by machine tags or groups

By Department

- View department-level performance

- Compare multiple departments side-by-side

- Analyze cross-departmental trends

By Shift

- Filter by specific shifts (Day, Night, Weekend, etc.)

- Compare shift performance

- Analyze 24/7 operations across all shifts

By Date Range

- Custom date range selection (any start and end date)

- Pre-defined ranges (Last 7 days, Last month, Last quarter, etc.)

- Year-over-year comparisons

- Specific event date ranges

By Time Interval

- Hourly: See performance broken down hour-by-hour

- Daily: Day-by-day analysis for week or month views

- Weekly: Weekly summaries for monthly or quarterly reports

- Monthly: Month-by-month trends for annual reviews

- Quarterly: High-level quarterly performance

- Yearly: Long-term trend analysis

Report Metrics

Advanced Reports display comprehensive metrics including:

Utilization Metrics

- Utilization %: Percentage of scheduled time actively producing

- Uptime: Total productive runtime

- Downtime: Total non-productive time

- Idle Time: Time between scheduled shifts or unassigned periods

Production Metrics

- Parts Produced: Total part count for the period

- Cycle Time: Actual average cycle time vs. target

- Production Rate: Parts per minute or hour

- OEE: Overall Equipment Effectiveness calculation

Time Breakdown

- Scheduled Time: Total time machines were expected to run

- Unscheduled Time: Time outside defined shifts

- Downtime by Category: Breakdown of downtime reasons

Performance Indicators

- Goal Achievement: Percentage of production goals met

- Trend Direction: Improving, declining, or stable performance

- Variance: Difference from targets or baselines

Common Use Cases

1. Monthly Executive Summary

Objective: Create a high-level performance report for management

Set date range

Select Last Month from the date range picker

Choose time interval

Set interval to Weekly to see 4-5 data points for the month

Select all machines (or by department)

Include all assets or filter by department for department-specific reports

Review key metrics

Focus on utilization %, total uptime/downtime, and parts produced

Export or screenshot

Export to CSV or take a screenshot for presentation slides

Result: Clean monthly summary showing weekly trends suitable for executive presentations

2. Shift Performance Comparison

Objective: Compare day shift vs. night shift performance

Set date range

Choose Last 2 Weeks or Last Month

Select time interval

Set to Daily to see day-by-day patterns

Run report for Day Shift

Filter by Day Shift and note the average utilization %

Run report for Night Shift

Change filter to Night Shift and compare results

Identify gaps

Look for significant differences in utilization, downtime, or production output

Result: Clear comparison showing which shift performs better and by how much

3. Department Benchmarking

Objective: Identify which department is most/least efficient

Set date range

Choose a consistent period (e.g., Last Quarter)

Set interval

Use Monthly to see consistent trends

Run reports for each department

Generate separate reports for each department

Compare metrics

Look at utilization %, downtime hours, and production output

Share best practices

Identify what top-performing departments are doing differently

Result: Ranked list of departments by performance with actionable insights

4. Improvement Initiative Tracking

Objective: Measure the impact of a process improvement or equipment upgrade

Define before period

Set date range for 4 weeks before the improvement

Run baseline report

Generate report and note average utilization and downtime

Define after period

Set date range for 4 weeks after the improvement

Run post-improvement report

Generate report with same filters and interval

Calculate impact

Compare utilization %, downtime reduction, and production increase

Result: Quantified ROI showing exactly how much the improvement helped

5. Specific Machine Deep Dive

Objective: Investigate a specific machine's performance over time

Select the machine

Filter to show only the machine in question

Set a long date range

Choose Last 3 Months or Last Quarter

Use Daily or Weekly interval

See trends without too much noise

Look for patterns

Identify recurring issues, degrading performance, or improvement trends

Cross-reference with downtimes

Use Downtimes page to see specific events during low-performance periods

Result: Complete performance history revealing patterns and root causes

Filtering Options Explained

Date Range Selection

Use the date picker to select a custom date range:

- Click the date range selector to open the calendar

- Choose start date and end date for your analysis period

- Apply the date range to filter your report data

This allows you to analyze any specific time period, from a single day to multiple years.

Time Interval Impact

The interval you choose dramatically affects how data is displayed:

| Interval | Best For | Data Points | Use Case |

|---|---|---|---|

| Hourly | Single day or shift | 8-24 per day | Detailed shift analysis |

| Daily | 1-4 weeks | 7-30 points | Weekly or monthly trends |

| Weekly | 1-6 months | 4-26 points | Monthly or quarterly reports |

| Monthly | 3-24 months | 3-24 points | Quarterly or annual reviews |

| Quarterly | 1-5 years | 4-20 points | Long-term strategic planning |

| Yearly | Multi-year | 2-10 points | Historical benchmarking |

Choose an interval that gives you 5-15 data points for easy visualization. Too few points hide trends; too many create noise.

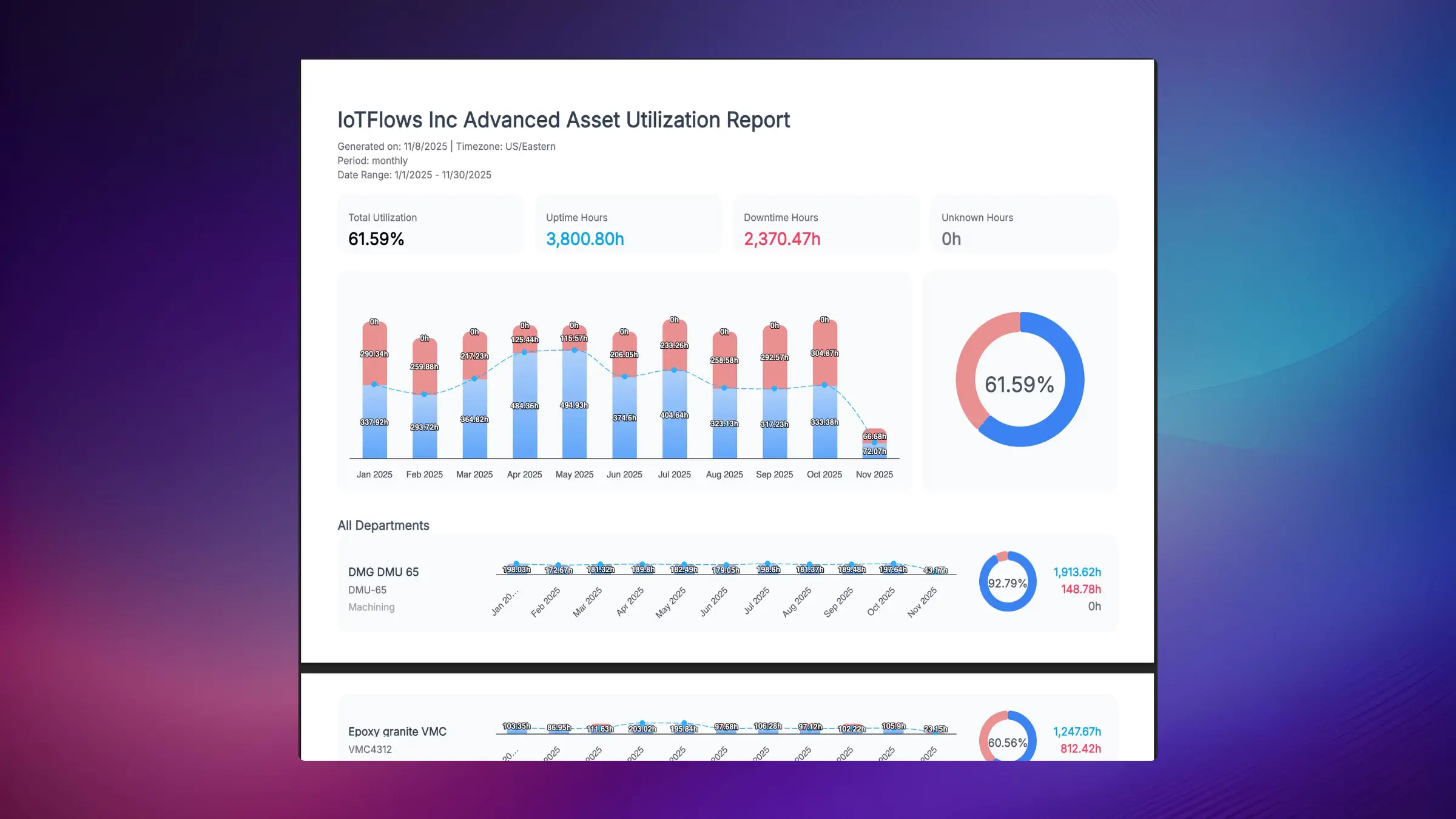

Exporting Data

CSV Export

Click the CSV button to download report data:

- All visible metrics included

- Formatted for Excel or Google Sheets

- Preserves filters and date ranges

- Use for custom analysis or integration with other systems

PDF Generation (if available)

Generate printer-friendly reports:

- Professional formatting

- Includes charts and summary tables

- Suitable for distribution to stakeholders

- Archival for compliance or records

Best Practices

1. Use Consistent Time Periods for Comparisons

When comparing performance (e.g., this month vs. last month), ensure:

- Same number of working days

- Same shift configuration

- Same machines included

- Account for holidays or plant shutdowns

2. Start Broad, Then Narrow

Begin with facility-wide reports, then drill down:

- All machines, monthly view → identify underperforming departments

- Department-level, weekly view → find specific problem machines

- Machine-level, daily view → pinpoint exact issues

3. Set a Regular Review Schedule

Establish recurring report reviews:

- Daily: Quick utilization check (Today, Hourly interval)

- Weekly: Team meeting report (Last 7 Days, Daily interval)

- Monthly: Management review (Last Month, Weekly interval)

- Quarterly: Strategic planning (Last Quarter, Monthly interval)

4. Bookmark Common Reports

If your platform supports it, save filter combinations for frequently-used reports to save time.

5. Combine with Other Tools

Advanced Reports answer "what" and "how much." Use other tools for deeper analysis:

- Downtimes page: Understand "why" performance was low

- Historical Production: Track specific part/operation trends

- Assets Overview: Real-time status and intervention

Interpreting Results

Identifying Trends

Improving Performance:

- Utilization % increasing over time

- Downtime hours decreasing

- Production output growing

- Action: Document what's working and maintain momentum

Declining Performance:

- Utilization % dropping over time

- Downtime hours increasing

- Production output falling

- Action: Investigate root causes immediately (aging equipment, operator turnover, process degradation)

Stable Performance:

- Consistent metrics across time periods

- Low variance between intervals

- Action: Good operational control, look for small optimization opportunities

High Variability:

- Large swings in utilization or output

- Inconsistent performance

- Action: Investigate causes of instability (unreliable equipment, inconsistent processes, training gaps)

Common Questions

Need help creating custom reports or interpreting results? Contact our support team at support@iotflows.com

Generate powerful downtime root cause analysis reports with advanced filtering and visualization options.

Enhance efficiency and accuracy with a smart, automated system that seamlessly tracks work sessions based on operator sign-ins.