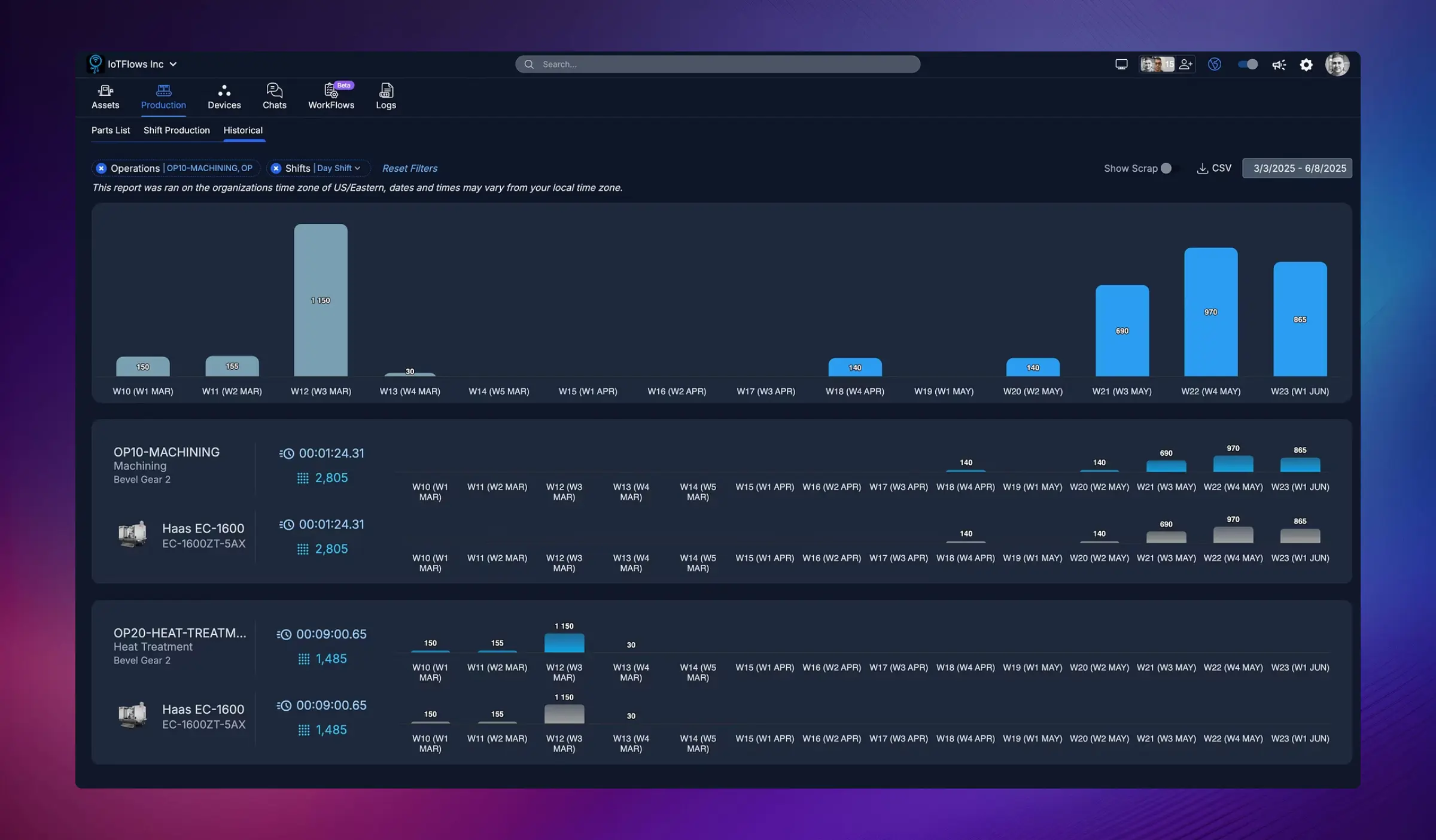

Historical Production

Analyze production trends over weeks and months with comprehensive historical views showing operation performance, throughput, and quality metrics.

Overview

The Historical Production page provides a powerful long-term view of your manufacturing output, allowing you to analyze production trends across weeks, months, quarters, and years. This page helps you identify patterns, track improvement initiatives, compare performance across time periods, and make data-driven decisions for capacity planning and process optimization.

Perfect for:

- Tracking production trends over extended periods

- Comparing week-over-week or month-over-month performance

- Evaluating the success of continuous improvement projects

- Planning capacity and workforce needs based on historical data

- Identifying seasonal or recurring production patterns

- Benchmarking current performance against historical baselines

What You Can See

The Historical Production page displays production data organized by operation/part with the following information:

Operation/Part Summary

- Operation Name and Part: The specific operation or part being tracked (e.g., "OP10-MACHINING", "Haas EC-1600")

- Total Parts Produced: Cumulative count for the selected time period

- Operation Details: Bevel gear types, machine models, or other identifying information

Weekly/Monthly Production Bars

Visual bar chart showing production quantities for each week or month in the selected date range:

- Height of bars indicates production volume

- Hover over bars to see exact part counts for that period

- Compare bars side-by-side to identify trends (increasing, decreasing, or stable production)

Time Period Labels

Clear labeling showing:

- Week numbers (e.g., "W10 (W1 MAR)", "W18 (W4 APR)")

- Month names for monthly views

- Quarters for quarterly analysis

- Years for annual comparisons

Filtering and Date Range

Choose custom date ranges to analyze:

- Last 4 weeks

- Last 3 months

- Last quarter

- Last year

- Custom date range (select specific start and end dates)

Filtering and Options

Filter by Operations

Select specific operations or parts to focus your historical analysis:

- Single operation to track one part's performance over time

- Multiple operations to compare performance side-by-side

- All operations for a comprehensive facility-wide view

Filter by Shifts

Choose which shifts to include in historical data:

- Day Shift only

- Night Shift only

- Weekend Shift

- All Shifts combined

Group By

Organize historical data by:

- Operation: Show each operation as a separate row

- Part: Group all operations producing the same part

- Machine: View production history by specific equipment

Sort Options

Sort historical data by:

- Total Production: Highest to lowest output

- Operation Name: Alphabetical order

- Trend: Operations with improving vs. declining output

Export Data

Download historical production data as CSV for:

- Custom analysis in Excel or analytics tools

- Executive reporting

- ERP system integration

- Long-term archival

Click the CSV button in the top-right corner to export the visible data.

Show Scrap Toggle

Enable the Show Scrap option to include rejected/bad parts in the visualization, allowing you to track quality trends over time.

Use Cases

1. Track Continuous Improvement Initiatives

When you implement process changes, use Historical Production to measure their impact:

- Compare production before and after the change

- Quantify improvements in throughput

- Validate ROI on improvement investments

- Share success stories with stakeholders

Example: After installing new tooling on a CNC machine, compare production for the 4 weeks before vs. 4 weeks after to measure the productivity gain.

2. Identify Seasonal Patterns

Analyze production across months and quarters to spot seasonal trends:

- Higher demand during specific months

- Staffing needs that vary by season

- Equipment utilization patterns

- Supply chain timing

Example: Discover that production drops every December due to holiday shutdowns and plan workforce reductions accordingly.

3. Capacity Planning

Use historical data to forecast future capacity needs:

- Determine if current equipment can handle projected demand

- Identify when additional machines or shifts are needed

- Plan capital expenditures based on growth trends

- Optimize workforce scheduling

Example: Historical data shows consistent 10% quarterly growth; use this trend to justify purchasing an additional machine before capacity is constrained.

4. Benchmarking and Goal Setting

Establish realistic production goals based on historical performance:

- Set targets that challenge teams while remaining achievable

- Identify "best week" performance and work toward making it consistent

- Compare current performance against historical peaks

Example: Historical data shows your best month ever was 5,000 units. Set a new goal to achieve 5,000+ units consistently.

5. Root Cause Analysis for Declines

When production drops, Historical Production helps you pinpoint when the decline started:

- Narrow the timeline for investigation

- Correlate production drops with other events (maintenance, personnel changes, supplier issues)

- Identify gradual degradation vs. sudden drops

Example: Notice production declining gradually over 6 weeks, investigate and discover worn tooling that needed replacement.

6. Compare Shift Performance

Analyze production trends by shift to identify training needs or operational issues:

- Compare day shift vs. night shift output over months

- Identify if one shift consistently underperforms

- Evaluate the impact of operator changes or training programs

Understanding the Visualizations

Bar Chart Interpretation

- Tall bars: High production weeks/months (good performance)

- Short bars: Low production periods (investigate why)

- Increasing trend: Production improving over time (continuous improvement working)

- Decreasing trend: Production declining (requires attention and root cause analysis)

- Consistent bars: Stable, predictable production (good operational control)

- Highly variable bars: Inconsistent production (indicates instability or external factors)

Missing Data

If no bar appears for a time period, it means:

- No production occurred during that period

- The operation wasn't yet set up in IoTFlows

- The machine was offline or disconnected

Best Practices

1. Review Historical Trends Regularly

Don't just focus on daily or shift-level performance. Set aside time monthly or quarterly to review long-term trends and identify strategic improvement opportunities.

2. Combine with Downtime Analysis

When production declines in historical data:

- Note the time period of the decline

- Navigate to the Downtimes page

- Filter by the same date range

- Identify root causes (excessive downtime, quality issues, etc.)

3. Document Changes and Events

Keep a log of significant events (equipment changes, process improvements, operator training, etc.) so you can correlate them with production trend changes visible in Historical Production.

4. Share Insights with Stakeholders

Use historical production charts in management reviews, team meetings, and improvement project presentations to demonstrate progress and justify investments.

5. Set Baselines for New Operations

When starting a new operation or part, establish a baseline by tracking production for the first 4-8 weeks. Use this as your reference point for future improvement.

Have questions about interpreting historical trends or improving production consistency? Contact our support team at support@iotflows.com